References

Setting standards instead of standard solutions

We advise, publish, discuss and provide important impulses for sustainability. Here you will find a selection of clients, projects and references.

They trust us

Companies and organizations that we have advised

References

Our case studies are currently only available on our German site.

further references

Where we publish, discuss and get involved. And what others say about us.

Here you will find an excerpt from our portfolio.

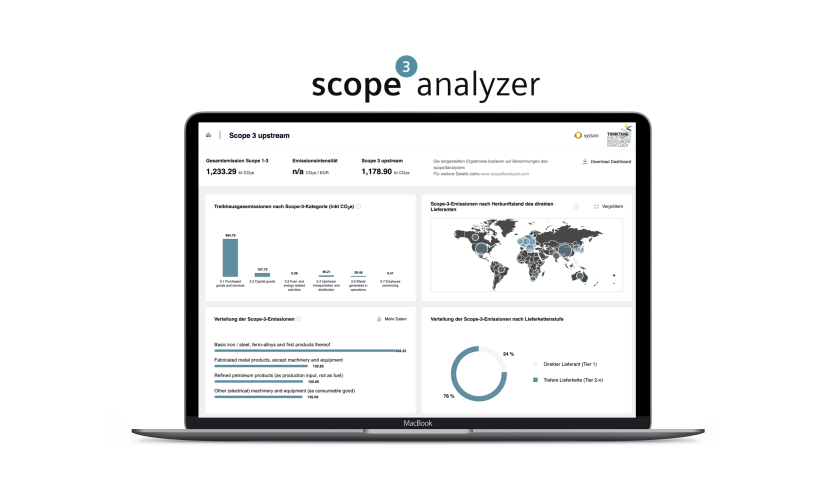

2022, Cooperation: scope3analyzer, a free carbon footprinting tool for Scope 3

The scope3analyzer is the easiest way for companies to get started with climate protection. The free tool can calculate CO2 emissions in scope 1, 2 and 3 directly on the basis of existing company data (e.g. purchasing data). Common standards such as the GHG Protocol and CDP as well as the SBTi accept the scope3analyzer methodology used. The tool was developed in collaboration with Systain Consulting GmbH, THINKTANK industrielle Ressourcenstrategien and the Institute for Industrial Ecology with the support of the Baden-Württemberg Ministry of the Environment. The ZEISS Group and Robert Bosch GmbH have piloted the tool as practice partners.

2022, study for the European Commission

With the draft of a European supply chain law, the EU Commission wants to increase the requirements for respecting human rights in the supply chain at EU level. Our sector study (“Supply Chain Atlas”) was used by the EU Commission to justify the planning of this law in its draft.

2019-2020, Cooperation: Consortium partner within the framework of the National Action Plan (NAP)

Systain was a consortium partner in the German government’s National Action Plan “Business and Human Rights” (NAP). We were commissioned to review the success of companies’ voluntary reporting on human rights due diligence. On the basis of this review, the German government was able to determine that not enough companies were fulfilling the requirements of human rights due diligence. This is how the Due Diligence Act, also known as the Supply Chain Act, came to light.

2019, Value Balancing Alliance

The Value Balancing Alliance (VBA), a corporate alliance with BASF, BMW, the Otto Group, SAP and others, was founded in 2019 with an ambitious goal: The VBA is developing a method that will become the standard for how companies measure their environmental and social impacts along the entire value chain – namely using monetary values. Systain is supporting the member companies Bosch and Otto Group in the application of this innovative methodology. Among other things, we used the VBA methodology and indicators to quantify the external effects of Bosch’s supply chains. This enabled us to gather strategic and methodological insights into the applicability of the methodology in the corporate context and develop recommendations.